Automobile bottom beam

Product Features

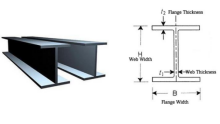

1. The bottom beam of the car is made of hot-rolled H-beam. Hot-rolled H-beam has stable quality due to one-time hot-rolling forming, and there are no various shortcomings such as weld cracks and low fatigue resistance at welds.

2. The use of hot-rolled H-beams to produce beams has few processes, high efficiency and short delivery time.

3. The steel structure of H-beam is high in strength. Compared with I-beam, the section modulus is large. When the bearing conditions are the same, it can save 10-15% of metal.

4. The structure is scientific and reasonable, with good plasticity and flexibility, high structural stability, and can withstand large vibration and impact loads

5. Save labor and material, compared with welding H-beam, it can obviously save labor and material, reduce the consumption of raw materials, energy and labor, low residual stress, and good appearance and surface quality.

1.

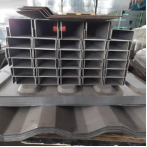

Type | Material | Yield Strength | Standards | Weight/kg | Conventional Product |

100*30*2.2*2.2 | 20MnVB | 600MP | GB | 2.76 | C-shaped steel |

101*57*2.3*3.2 | GR50 | 500MP | IFI | 4.71 | import |

117*66*2.7*3.2 | GR50 | 500MP | DIN | 5.83 | import |

446*150*7*12 | LG510LH | 400MP | GB | 52.58 | H beam |

482*153.5*10.5*19 | LG510LH | 400MP | GB | 83.52 | H beam |

492*150*7*12 | LG510LH | 400MP | GB | 55.11 | H beam |

500*146*6*14 | LG510LH | 400MP | GB | 55.46 | H beam |

504*153*10*18 | LG510LH | 400MP | GB | 81.11 | H beam |

2.

3.

steel | Mechanical properties | 180° bending test | |||

Yield Strength | tensile strength | Elongation | Akv/J | ||

> | |||||

LG510LH | 400 | 510-660 | 19 | 34 | d=2a |

Related News

Submitted successfully

We will contact you as soon as possible