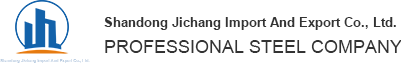

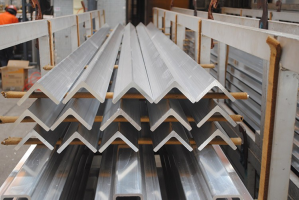

Aluminum profile angle bar

1.low density and light weight.

2.strong corrosion resistance.

3.good ductility and high quality materials.

4.strong plasticity and good productivity.

5.good casting properties, can be processed into aluminum profiles of different shapes.

6.The surface treatment performance is good, the appearance of bright color.

7.Chemical properties are stable, non-magnetic, can be recycled.

Perspective Aluminum is a kind of aluminum extrusion profile, that is an prolonged strip of aluminum with facets perpendicular to every different. the form is simple and there may be no precise requirement for load-bearing. The attitude is normally 90°, and there are also 45° and 135°.

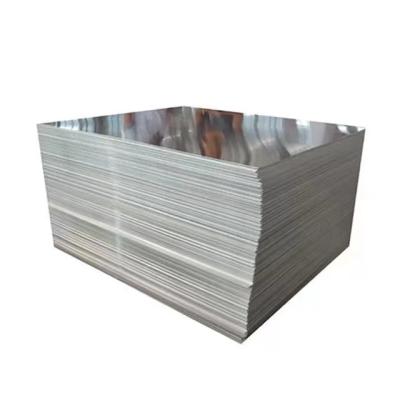

In appearance, there are equal-angle aluminum, unequal-angle aluminum, and rounded-angle aluminum, which are generally used in the field of decoration. The decorative corner aluminum generally needs spraying or electrophoresis treatment, and is generally fixed with cement nails. Used for edge sealing and accessories, usually thin and low cost. Industrial angle aluminum is generally thicker, and is mainly used for connecting parts and angle brackets. The size can be customized. After cutting and punching, it is used for connection and fixing between profiles.

Steel Angle is widely used in various building structure ad engineering structure:Beam, bridges, construction ,communications tower ,ship;transmission tower, reaction tower, warehouse goods shelves;lifting transportation machinery,agricultural machine making; industrial furnace;contaner

All profiles are surface treated to help prevent oxidation and corrosion, while offering a matte finish. To meet other usage requirements, we can supply powder coatings with RAL colour codes, which can be chosen according to your needs.

We have a wide range of aluminum angle profile moulds. The main benefit of existing molds is to save you mold costs and production time.

Specification: our ready tools or as per customer's drawing (DWG, DXF, 3D drawings)

Aluminum Alloy Grade: 6063, 6061, 6463, 6082, 3003, 7075 etc.

Surface Treatment: anodized, electrophoresis, powder coated, wood grain, PVDF, AkzoNoble coated, brushed, polished, sandblasted CNC Machining is available as per customer's drawing (DWG, DXF, 3D drawings)

6000 series aluminum angle is the most commonly used aluminum for structural applications. It has above average corrosion resistance, good machinability, and is excellent for welding

Steel Angle is widely used in various building structure ad engineering structure:

Beam, bridges, construction ,communications tower ,ship;transmission tower, reaction tower, warehouse goods shelves;lifting transportation machinery,agricultural machine making; industrial furnace;contaner

All profiles are surface treated to help prevent oxidation and corrosion, while offering a matte finish. To meet other usage requirements, we can supply powder coatings with RAL colour codes, which can be chosen according to your needs.

We have a wide range of aluminum angle profile moulds. The main benefit of existing molds is to save you mold costs and production time.

Specification: our ready tools or as per customer's drawing (DWG, DXF, 3D drawings)

Aluminum Alloy Grade: 6063, 6061, 6463, 6082, 3003, 7075 etc.

Surface Treatment: anodized, electrophoresis, powder coated, wood grain, PVDF, AkzoNoble coated, brushed, polished, sandblasted CNC Machining is available as per customer's drawing (DWG, DXF, 3D drawings)

6000 series aluminum angle is the most commonly used aluminum for structural applications. It has above average corrosion resistance, good machinability, and is excellent for welding

Specification

Product Name | aluminum angle bar(6063) |

Place of Origin | Shandong, China |

Grade | 5000/6000 /7000Series etc. |

Temper | T3-T8,T5,T6 |

Size | Customized, same as drawings or samples |

Shape | As Customized,Square, Rectangle, Round, Flat, Angle, T profile etc. |

Alloy Or Not | Is Alloy |

Service | OEM/ODM |

Color | Customized Color |

MOQ | 500KG |

Thickness | 0.8MM-20MM or Customized |

Surface treatment | Mill finish, Anodizing, Powder Coating, Electrophoresis, Wood Grain, Polishing |

Products accept custom sizes and colors

Deep Processing:Drilling, punching, bending, CNC, aluminium profile fabrication, Precise cutting etc.

Application

doors and windows, kitchen, equipment frame, industry, curtain wall, solar, decorations, transportation tools, and other constructions or building area.

Packing

1. Bundles Packing: |

-- Inside: packed with plastic protective film to protect each piece |

-- Outside: Wrap to be bundles by waterproof craft paper or EPE film. |

2. Carton Packing: |

--Inside: Each pcs pack in one plastic bag; |

--Outside: Numbers of quantity put in one carton. |

3. Wood Pallet Packing: |

-- Inside: Bundles or cartons packing; |

-- Outside: Numbers of bundles or cartons laden on one wood pallet. |

4. Customized packing requirement available. |

Related News

Submitted successfully

We will contact you as soon as possible