Welding principle:Relying on the heat conduction of the base metal, and a little auxiliary flame to melt the welding wire to form.Welding method:1. Cleaning: Mechanical cleaning is the best way to clean the welded parts, the purpose is to remove the surface oxide film.2. Heating: Focus on heating with thick parts. When heating, it can be a little farther away from the welding point, instead of directly burning the welding port.3. Blanking: When the temperature reaches 400 degrees, lower the welding wire.

Contact Now

Chinese name:低温铝焊条welding wire:ER4047,ER4043melting point of pure aluminum:660.37 degrees Celsius380-450 welding wire Q303, WE-Q303B, WE53Industry scope1. The socket connection of aluminum pipes in the refrigeration industry, the dissimilar welding of copper and galvanized pipes for central air conditioning, stainless steel pipes, and aluminum pipes.2. Welding of aluminum terminals, aluminum leads and aluminum conductive bars in the substation industry.3. Welding of radiator tubes, motors and busbars in the electronic and electrical industry.4.

Contact Now

Product advantages:With special chemical and physical houses, it isn't always only mild in weight, company in texture, but also has correct ductility, electrical conductivity, thermal conductivity, heat resistance and nuclear radiation resistance.Product introduction:Aluminum rod is a kind of aluminum product. The melting and casting of aluminum rod includes melting, purification, impurity removal, degassing, slag removal and casting process.

Contact Now

Product advantages:With special chemical and physical properties, it is not only light in weight, firm in texture, but also has good ductility, electrical conductivity, thermal conductivity, heat resistance and nuclear radiation resistanceProduct introduction:Aluminum rod is a kind of aluminum product. The melting and casting of aluminum rod includes melting, purification, impurity removal, degassing, slag removal and casting process.

Contact Now

Welding method1. Cleaning: Mechanical cleaning is the best way to clean the welded parts, the purpose is to remove the surface oxide film.2. Heating: Focus on heating with thick parts. When heating, it can be a little farther away from the welding point instead of directly burning the welding port.3. Blanking: When the temperature reaches 400 degrees, lower the welding wire.

Contact Now

Product advantages:With unique chemical and physical houses, it isn't always only moderate in weight, organisation in texture, however additionally has accurate ductility, electrical conductivity, thermal conductivity, warmness resistance and nuclear radiation resistance.Product introduction:Aluminum rod is a kind of aluminum product. The melting and casting of aluminum rod includes melting, purification, impurity removal, degassing, slag removal and casting process.

Contact Now

The aluminum profile is a relatively common material in social production. Its excellent performance and many advantages are favored in most industries.H-beam is an economical section steel with better section mechanical properties than I-beam. It is named because the shape of the section is the same as the English letter "H", people usually think of I-beam and H-beam as a kind of profile, in fact, the two are different.

Contact Now

Aluminum profile is a relatively common material in public production. Its excellent performance and many advantages are in demand in most industries.I-beam is an economical profile steel with better sectional mechanical properties than I-beam. It is named because the section shape is the same as the English letter "H", people usually think of H-beam and H-beam as a kind of profile, in fact they are different.

Contact Now

Aluminum profile is a relatively common material in social production. Its excellent performance and many advantages are favored in the majority of industries.H-beam is an economical section steel with better section mechanical properties than I-beam. It is named because the shape of the section is the same as the English letter "H", people usually think of I-beam and H-beam as a kind of profile, in fact, the two are different.

Contact Now

Aluminum profile is a relatively common material in social production. Its excellent performance and many advantages are favored in the majority of industries.H-beam is an economical section steel with better section mechanical properties than I-beam. It is named because the shape of the section is the same as the English letter "H", people usually think of I-beam and H-beam as a kind of profile, in fact, the two are different.

Contact Now

Product advantages: It not only takes advantage of the excellent electrical conductivity of copper and the light weight of aluminum, but also overcomes the disadvantages of easy oxidation of aluminum, high contact resistance, and difficult welding of joints, and greatly saves my country's scarce copper resources, reducing cost of conductors.

Contact Now

Product advantages:The square steel increases the tensile force of the structure, the appearance is beautiful, and the capital cost is greatly reduced; the edges and corners are clear and the diameter is accurate.Product description:Square steel is solid, bar stock. Different from square tubes, hollow ones belong to pipes. Steel: It is a material of various shapes, sizes and properties required by ingot, billet or steel processed by pressure. Steel is an essential and important material for national construction and the realization of the four modernizations.

Contact Now

H-beam is an economical section steel with better section mechanical properties than I-beam. It is named because the shape of the section is the same as the English letter "H", people usually think of I-beam and H-beam as a kind of profile, in fact, the two are different. We can distinguish from appearance and use.Aluminum profile is a relatively common material in social production.

Contact Now

Product advantages:It no longer most effective takes gain of the outstanding electrical conductivity of copper and the light weight of aluminum, but additionally overcomes the risks of smooth oxidation of aluminum, excessive contact resistance, and tough welding of joints, and substantially saves my u . s .'s scarce copper resources, lowering fee of conductors.

Contact Now

Product advantages:The square metal will increase the tensile pressure of the shape, the arrival is lovely, and the capital cost is substantially reduced; the rims and corners are clean and the diameter is correct.Product description:Square steel is solid, bar stock. Different from square tubes, hollow ones belong to pipes. Steel: It is a material of various shapes, sizes and properties required by ingot, billet or steel processed by pressure. Steel is an essential and important material for national construction and the realization of the four modernizations.

Contact Now

Aluminum telescopic tube is a kind of non-ferrous metal tube, which refers to a metal tubular material which is hollow along its longitudinal direction by extrusion processing of pure aluminum or aluminum alloy.There may be one or more closed through holes, with uniform wall thickness and cross section, and supplied in straight or roll form. Widely used in automobiles, ships, aerospace, aviation, home appliances, agriculture, electromechanics, home appliances and other industries.Various types and styles of aluminum extrusion profiles can be customized.

Contact Now

Aluminum groove is a not unusual aluminum extrusion material. compared with different materials such as metallic or iron, the cost of aluminum extrusion die is decrease than that of forging. the aluminum alloy aluminum extrusion profile can achieve the maximum structural efficiency, and the aluminum profile may be used where the energy desires to be expanded, and it could be removed where it is not wanted.

Contact Now

The aluminum corrugated core composite panel is a metal ceiling with a composite panel structure. The panel is made of high-quality high-strength aluminum alloy sheet, and the core material is corrugated by automatic mechanical rolling or continuous stamping, and the material strength is increased. The bonding of the board is completed by high temperature and high pressure using aerospace hot melt. The panel can be punched, and the back is covered with sound-absorbing non-woven fabric, which can be used as a sound-absorbing ceiling.

Contact Now

Color aluminum tube appearance is beautiful, can be customized according to customer requirements.The tube is a type of non-ferrous metallic tube, which refers to a metallic tubular cloth this is product of natural aluminum or aluminum alloy through extrusion processing to be hole alongside its longitudinal length. Specification for Round tubeSIZECostomizedWTCostomizedLength1-12m1) Grade:1000Series:1050/1060/1100/1145/1199/13502000Series:2011/2014/2017/2024/2036/2048/2124/2218/2219/2A02/2A06/2A10/2A11/2A12/2A14/2A16/2A17/2A50/2A60 3000Series:3003/3004/3105/3A21&n

Contact Now

Embossed aluminum roll embossing mainly includes classic orange peel pattern, worm pattern, water drop pattern, diamond pattern, hammer pattern, bean pattern, diamond pattern, pebble pattern, water ripple, shell carving pattern and so on. Embossed aluminum coil is pressed straight to form embossed aluminum plate. Embossed aluminum plate is made on the basis of aluminum plate.

Contact Now

Product DescriptionRoofing Coil Sheet 18-76-900 Wave Roofing Sheet Competitive Price Corrugated Aluminum TileProduct DescriptionAluminum corrugated board, also known as corrugated aluminum board, profiled aluminum sheet, aluminum tile, etc., is a profiled board that uses aluminum sheet to be rolled and cold-formed into various waves. It is suitable for industrial and civil buildings, warehouses, special buildings, and large spans.

Contact Now

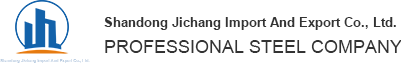

Angle aluminum is a kind of aluminum extrusion profile, which is a long strip of aluminum with two sides perpendicular to each other. The structure is simple and there is no special requirement for load-bearing. The angle is generally 90°, and there are also 45° and 135°. In appearance, there are equal-angle aluminum, unequal-angle aluminum, and rounded-angle aluminum, which are generally used in the field of decoration. The decorative corner aluminum generally needs spraying or electrophoresis treatment, and is generally fixed with cement nails.

Contact Now

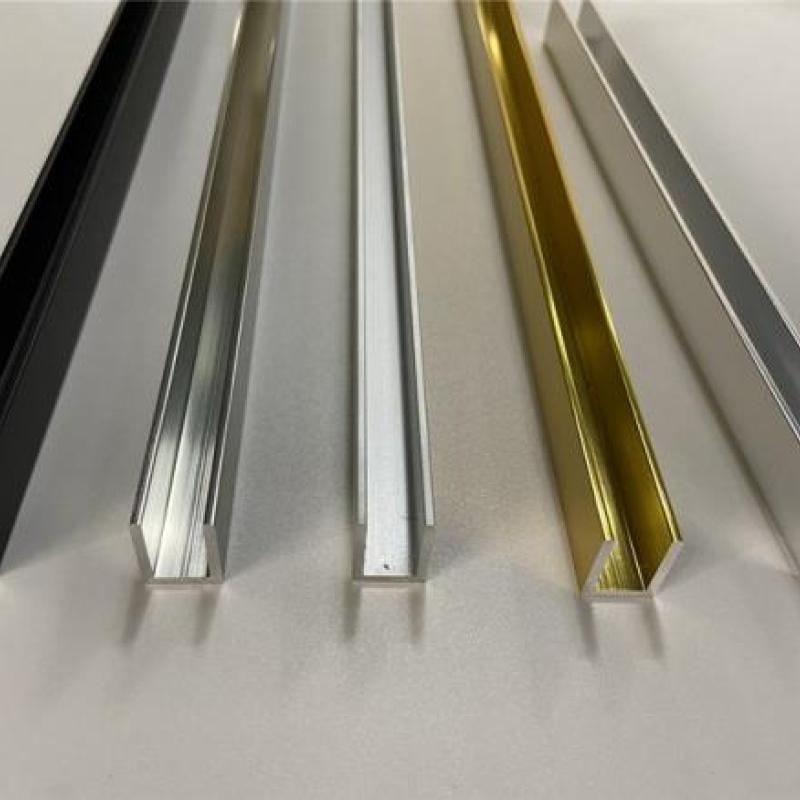

OverviewColor-coated aluminum plate, as the name implies, is to colorize the surface of aluminum plate. Common ones are fluorocarbon color-coated aluminum and polyester color-coated aluminum. Its performance is very stable, and it is not easy to be corroded. After special treatment, the surface layer can be guaranteed for 30 years.

Contact Now

OverviewColour-lined aluminum plate, because the name implies, is to colorize the surface of aluminum plate. common ones are fluorocarbon colour-lined aluminum and polyester coloration-covered aluminum. its performance could be very stable, and it is not smooth to be corroded. after unique remedy, the floor layer may be assured for 30 years.

Contact Now